Fully automated hardness tester, which can measure the hardness of metallic materials by Rockwell, Brinell, Vickers methods. Individual methods can be agreed directly with the customer.

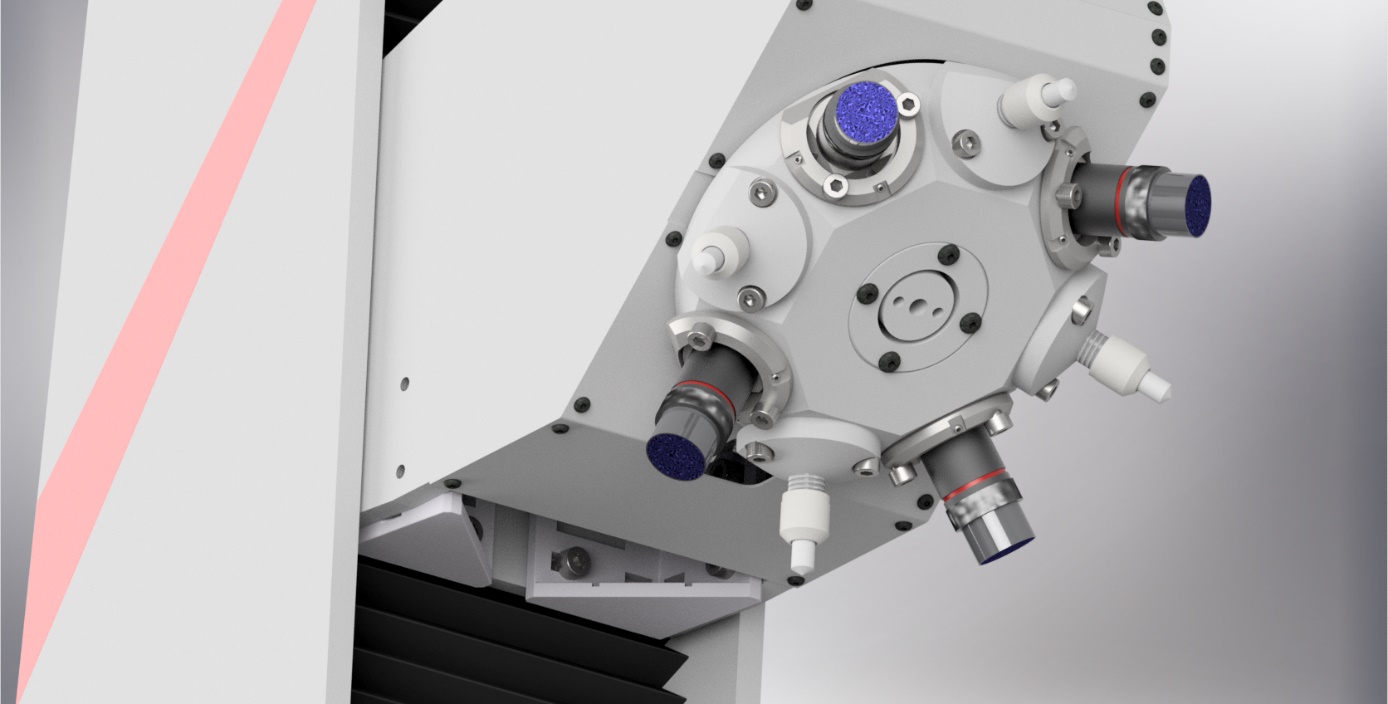

The hardness tester is equipped with a turret, which allows a very fast change of the indenters and lens without mechanical intervention of the operator. The indenters and lens are set automatically, according to the selected measurement method via PC. The turret provides space for 8 indenters or lenses.

Imprint scanning is performed by a sensitive, high-resolution CCD camera, which is essential for accurate processing of measured results. Depending on the selection, the measurement option is either automatic image analysis or touchpad settings manually via the touch screen.

The device can be equipped with a preview camera that has a wide-angle shot. This camera displays the entire surface of the sample / measured piece on the screen of the instrument and you can select the places you want to measure and where the imprints will be made. The device then automatically measures the selected locations. You can return to the measured results at any time and measure them individually.

A removable cross table is used to easily move samples, measure layers or create various measuring patterns of the instrument. Its movement is realized in the axes "X" and "y" via the joystick or on the screen via the program.

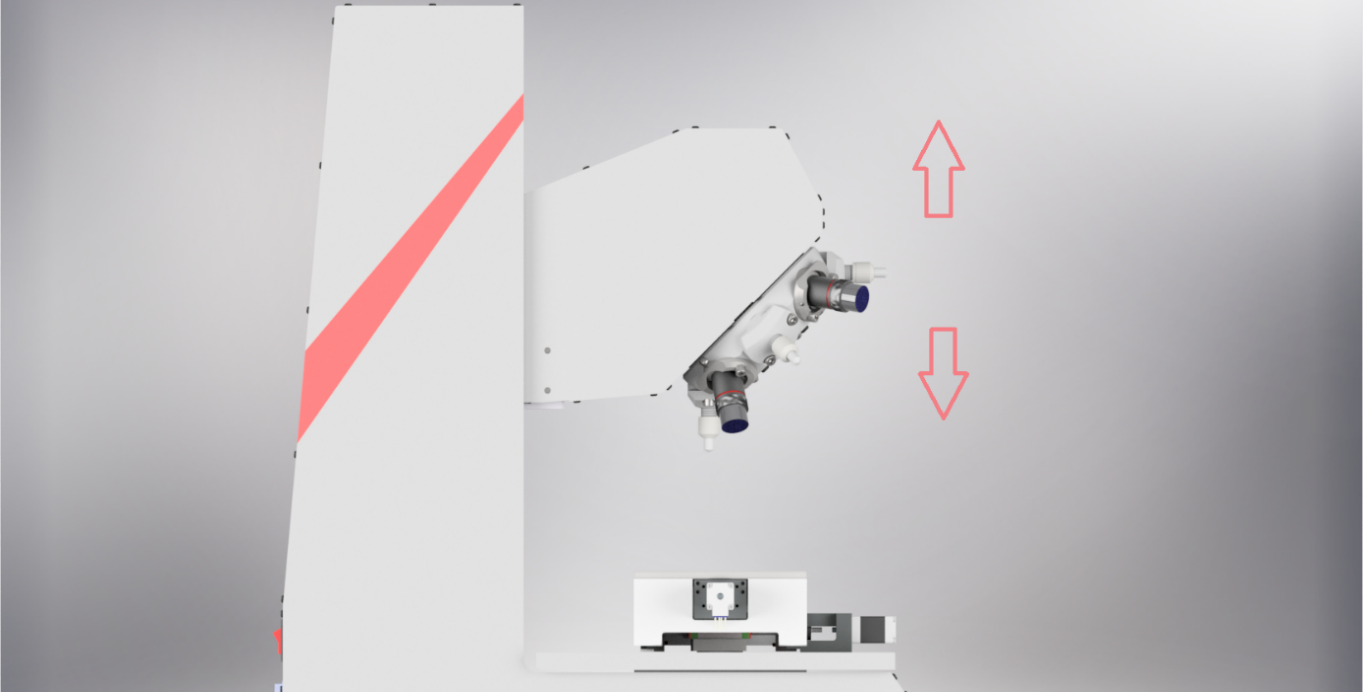

The movement of the "Z" axis can be agreed directly with the customer. Standard max. height is 350 mm (can be more or less). This height is positioned by means of an appropriate joystick, which moves the entire measuring head in the "Z" axis, together with the turret as required. Fast feed or fine feed for sharpening is available.

The device is able to automatically evaluate the given impression and also automatically focus on the surface of the given sample via the Autofocus function

Test methods and force loading:

The following devices are available to choose from: HT 250 UNI; HT 750 UNI; HT 3000 UNI. Individual methods can be agreed directly with the customer.

HT 250 UNI:

- maximum measuring range up to max. 2 452.5 N;

Measuring methods:

- Brinell: HBW2,5/15,62; HBW2,5/31.25; HBW2,5/62,5; HBW2,5/187,5; HBW 5/25; HBW 5/62.5; HBW 5/125; HBW 5/250 according to EN 6506 and ASTM.

- Vickers: HV1, HV5, HV10, HV15, HV20, HV30, HV40, HV50, HV100 according to EN 6507 and ASTM.

- Rockwell: HRA, HRB, HRC–HRV, HR15-N/T; HR30-N/T; HR45-N/T; according to EN 6508 and ASTM.

HT 750 UNI

- maximum measuring range up to max. 7 357,5 N;

Measuring methods:

- Brinell: HBW2,5/15,62; HBW2,5/31.25; HBW2,5/62,5; HBW2,5/187,5; HBW 5/25; HBW 5/62.5; HBW 5/125; HBW 5/250; HBW 5/750 according to EN 6506 and ASTM.

- Vickers: HV1, HV5, HV10, HV15, HV20, HV30, HV40, HV50, HV100 according to EN 6507 and ASTM.

- Rockwell: HRA, HRB, HRC–HRV, HR15-N/T; HR30-N/T; HR45-N/T; according to EN 6508 and ASTM.

HT 3000 UNI

- maximum measuring range up to max. 29 430 N.

Measuring methods:

- Brinell: HBW2,5/15,62; HBW2,5/31.25; HBW2,5/62,5; HBW2,5/187,5; HBW 5/25; HBW 5/62.5; HBW 5/125; HBW 5/250; HBW 5/750; HBW 10/3000 according to EN 6506 and ASTM.

- Vickers: HV1, HV5, HV10, HV15, HV20, HV30, HV40, HV50, HV100 according to EN 6507 and ASTM.

- Rockwell: HRA, HRB, HRC–HRV, HR15-N/T; HR30-N/T; HR45-N/T; according to EN 6508 and ASTM.

General software description:

It is a new software for data collection and statistical evaluation of hardness testers, which work according to the method of Vickers, Brinell and Rockwell. This product makes full use of the network and allows automatic export of data to a SQL server for further processing. The measurement results are also accessible to other users if required. The software allows special control for the universal hardness tester and its configuration.

The supplied software also allows:

- Image processing from the preview camera,

- image processing from a sensitive CCD camera,

- creation of measurement formulas on the preview camera,

- adjust the height of the measuring head,

- determination of the individual steps of the cross table and the measuring head,

- setting of individual axes,

- autofocus,

- automatic or manual evaluation of created imprint,

- evaluation and display of measured data and automatic calculation of layer thickness after chemical - thermal treatment,

- Jominy's hardenability tests on the screen and its graphical representation,

- archiving of data in the database,

- direct printing of measured and processed results, etc...

The computer has the Windows 10 operating system, the hardness tester software and the necessary drivers required for the correct operation of the automatic hardness tester installed.

Characteristic features of the software

- Choice of communication language: Slovak, Czech, German, English

- Selection of test methods

- Reverse test modification

- Statistical functions

- Automatic data transfer over the network

- Analysis and processing of measured data

- Conversion of the measured value to another methodology

- Print certificates in the selected language

- Perform measurement from PC

- Possibility to insert the company logo