Option to choose the level of equipment according to your needs.

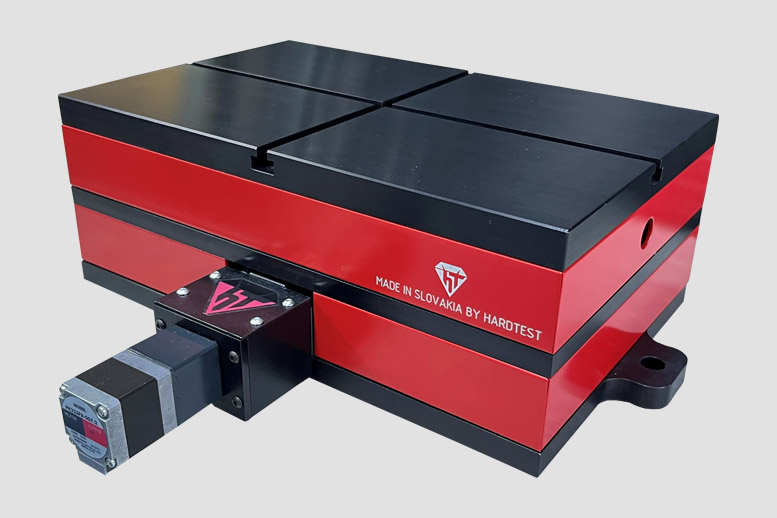

Very quick and easy operation of the automatic hardness tester, which measures the hardness of metal materials using the Rockwell / SuperRockwell methods according to the STN EN ISO 6508 standard and partially Brinell according to the STN EN ISO 6506 standard.

The device is equipped with a control computer with an operating system MS Windovs and new software for the collection and statistical evaluation of hardness tester data, which work according to the given methodologies. This product makes full use of the network and enables automatic data export to the server for further processing.

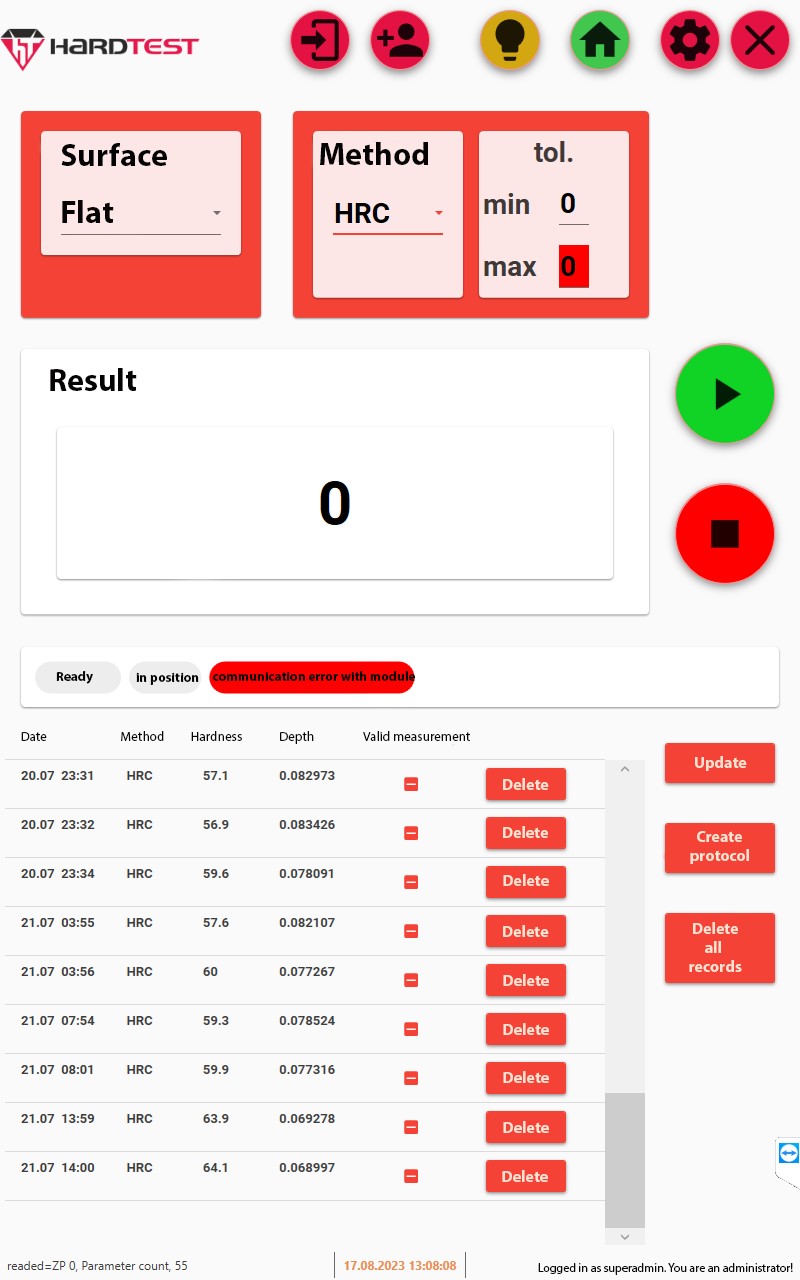

After performing the test on the motorized hardness tester, the hardness value is evaluated directly on the display depending on the chosen measurement methodology. The methodology of the relevant measurement is selected before starting the measurement.

The control part in the computer allows you to start the measurement cycle automatically when in contact with the sample or from the screen, to select the course of the measurement in automatic or manual mode. This minimizes the measurement error caused by operating the device. The operator chooses the length of the measurement cycle, which enables the measurement itself to be accelerated.

For a more efficient way of measuring and handling, the device is equipped with a motorized movement of the measuring head with a fast-forward function. Manipulation with the measured piece or with the sample is very quick and easy in this case. This system is effective for measuring pieces of different sizes and shapes. Significantly reduces the time required for handling and measuring pieces/samples. The device is equipped with active protection of the intendor against collisions.

The device is equipped with a self-clamping sample holder and an automatic hardness measurement system using selected methodologies.

The device can be equipped with a turret or a flip mechanism for the implementation of several penetrating bodies (Diamond cone 120°; Carbide ball 1/16"... ) without having to manually change the tips. The operator does not have to mechanically replace the penetrating bodies.

It is possible to implement a cross table (motorized or manual) on the device for simple evaluation, e.g. Jomini tests of hardenability, layers, depth of hardening and the like.

The customer can define the sample clamping system, the shape of the holder, the size of the table, the equipment, the content of the program, the feeds, the design, and so on.

The device enables direct evaluation and display of measured data on the screen, data archiving in the database and printing of measured and processed results on a connected printer. The control part in the computer allows you to start the measurement cycle of the hardness tester from the screen, to select the course of the measurement in automatic or manual mode. This minimizes the measurement error caused by operating the device. The operator chooses the length of the measurement cycle, which enables the measurement itself to be accelerated.

The version configured by you

- The customer himself determines the equipment and capabilities of the device according to his own requirements.

- We will be happy to help you choose the right one for your needs.

The control computer of the device allows

- choose the measurement methodology (automatic configuration)

- enter the measurement time

- set date and time

- set communication language: English, German, Slovak, Czech

- corrections for uneven surfaces

- conversion to other scales according to DIN 50 150

- determining the depth of the impression and the strength of the material

- measurement history

- data transfer to PC or FLASH

- after connecting the printer, print the created logs in the selected language

- checking the sensor settings

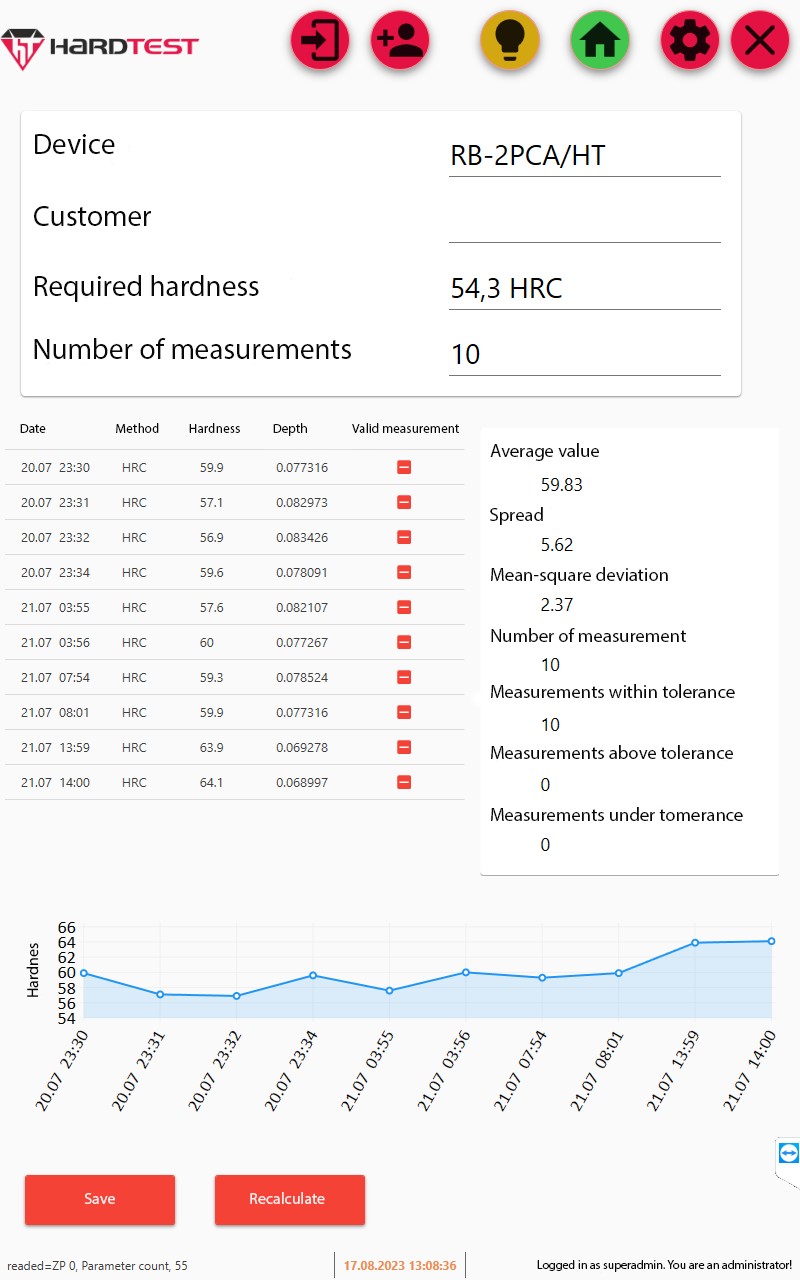

- statistical processing of results

- graphical representation of results

- archiving

- direct printing of certificates

- turning on/off the light

- modifications of measurements

- creating users and managing them

- corrections

Overview of the program environment for the hardness tester:

Preview of the environment for creating a protocol from a measurement:

Methods that you can measure with the device

Rockwell / SupperRockwell

DIN EN ISO 6508, ASTM E-18

Common Rockwell methodologies: Preload 10 kgf, main load 60 kgf | 100 kgf | 150 kgf

HRA | HRB | HRC | HRD | HRE | HRF | HRG | HRH | HRK | HRL | HRM | HRP | HRR | HRS | HRV

Super Rockwell (Surface hardness) ; Preload 3 kgf, main load 15 kgf | 30 kgf | 45 kgf

15N | 30N | 45N | 15T | 30T | 45T | 15W | 30W | 45W |15X | 30X | 45X | 15 Y| 30 Y| 45Y

Brinell - method from depth

- HBW 2,5/31,25

- HBW 2,5/62,5

- HBW 2,5/187,5

Technical specifications

- Height - 750 mm

- Width - 220 mm

- Depth - 550 mm

- Max. height of the tested sample - 310 mm (possible increase upon agreement - adjustment of the device)

- Weight - 80 kg